Article content

„Delicious taste. Suitable for both hot and cold cooking. Part of a varied and balanced diet. Supports a healthy lifestyle. Contains beneficial fats.“, Etc …

Such are the claims that promote margarines and other plant-based spreads.

So let’s take a closer look at how this incredibly “healthy”, practically gourmet treat is made.

Step 1: Selection of ingredients

The primary ingredients of margarines are usually the cheapest and at the same time the worst oils.

They are mostly made from soybean, corn, cottonseed or canola oil.

Occasionally some healthy olive oil is added. What matters, however, is what happens to these oils afterwards.

Step 2: Oil extraction

The quality of the oil and its usable components, besides the type itself, largely depends on the method of processing.

Oils intended for margarine production are obtained by applying high temperatures and pressure.

This is the least suitable method of obtaining oils. That is, the least suitable in terms of health effects. From an economic perspective it is the most efficient.

You might also be interested in: These small kernels far outperform any chemotherapy in cancer

During it, almost all beneficial components are destroyed on one hand and harmful substances are created on the other.

Step 3: Oil refining

After the first phase of oil recovery comes the phase of refining them.

During it very harmful chemicals are used, such as hexane and various solvents.

Unfortunately, traces of these substances permanently remain part of the final product that you spread on bread or use to bake cakes.

Step 4: Removal of vitamins

Now the oil is sufficiently oxidized and rancid. To be sure, it is further treated with hot steam.

During this process even the last few vitamins and minerals that remained after the previous processing are removed.

What is important, however, is that pesticides and solvents remain.

Step 5: Mixing with nickel

At this stage a nickel catalyst is added to the mass.

We no longer prefer to call it oil, but a mass, because what the original oil has turned into can hardly be called oil anymore.

The health effects of nickel are extensive. Among the milder are, for example, hypersensitivity and allergies to nickel in people (which is why it is no longer added much to coins today).

More serious health consequences of nickel include:

- increased risk of lung, nasal cavity and prostate cancer

- pulmonary embolism

- respiratory failure

- birth defects

- asthma and chronic bronchitis

- cardiovascular diseases

We could continue listing more, but we don’t want to scare you too much. You’ve probably formed an image based on the above.

Step 6: Hydrogenation

The mass from the previous step is exposed to hydrogen gas in a high-pressure reactor at high temperature.

Hydrogen bonds to the fat molecules of the mass and alters their chemical structure. That’s why these oils are also called hardened.

Hydrogenation raises their melting point. That’s why margarines, unlike oils, remain solid even at room temperature.

The problem is that such chemically altered fats have completely different biological and metabolic effects. They cause quite a lot of confusion in the human body.

Step 7: Emulsification

In previous steps a number of other ingredients were added to the oily mass. But as we know, not all substances can be mixed into a homogeneous form that easily.

Therefore emulsifiers are added in this step to ensure that the final liquid is nicely and evenly mixed.

And mainly, so that it stays that way for some time.

Otherwise its components could separate over time, as happens for example with cut beer or milk with cream on top and the rest of the milk underneath.

Step 8: Deodorization

After the alchemy so far you can probably guess how terribly our margarine mass must smell… I personally once visited a margarine factory and I wouldn’t wish that smell on you.

And because at a certain stage it is necessary to remove all those odors, that is done right now. Hot steam is used for that, similar to step four.

Step 9: Bleaching

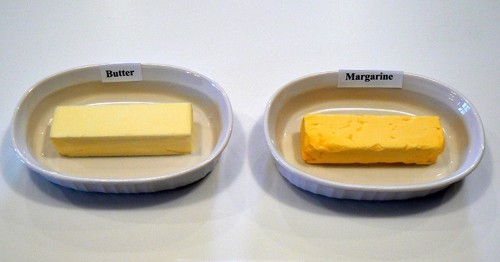

Margarines as the final product you buy in stores have a nice white color, or rather a yellowish tint.

But that is not their natural color.

Without technical bleaching (similar to how paper or laundry is bleached) they would be unattractively gray. So they are nicely whitened using technical bleaches.

And yes, you guessed correctly, some of the bleaching agents remain in them. Keep that in mind the next time you spread plant-based spreads…

And do you know what is the worst thing about the whole matter?

That you are exposed to margarine not only when you directly consume it as a spread on bread or use it in cooking.

Today it is already part of a large number of other products such as Horalky, cookies, cookies, pastries, desserts, cakes, some types of baked goods and many others.

Step 10: Adding vitamins, colorings and flavors

From the description so far you can probably imagine how margarine would taste at this stage of production. You would buy it only once and after the first bite it would likely end up in the bin.

However, their manufacturers wouldn’t make much profit in the long run that way. So in this step they flavor and color them.

From a marketing standpoint taste and color are no longer enough today. Therefore they also add some vitamins to our dead mass (which they removed earlier), essential fatty acids, or other substances.

Then in advertisements they will tell you a hundred times how healthy their products are for you… Better to tactfully stay silent about the fact that this is only 0.1% of their volume.

Step 11: Packaging

So, we’re slowly approaching the finish. But the mass still needs to be nicely packed into tubs or boxes with pretty pictures.

Of course, the entire production process takes place on the most modern machinery lines and in a hygienically impeccable environment.

Who would care anymore about what is actually hidden in the tubs. The main thing is that it was produced according to all those European standards, ISO regulations and various bureaucratic rules.

After all, form matters much more today than the actual content.

The main thing is that there won’t be any contamination in them. The fact that the product itself could be called a contamination is not important at all.

Step 12: Promoting margarine as a healthy product

So after a long journey of hardships, refining and bleaching, our margarine finally reaches the store shelves.

In parallel, a strong advertising campaign runs in the media emphasizing health claims of all sorts, that their margarines are healthy, that they lower cholesterol, blood pressure and the like.

Examples of the most common misleading claims about margarines:

- they contain no saturated fats (in reality those are important for humans)

- they contain no cholesterol (so from what is the body supposed to make hormones?)

- easy to digest (sure, try eating a plastic mold and see how your body digests that)